Founded in 1955 as Herrería Vulcano, our company evolved to become a strategic partner for main players in the industry, supporting complex manufacturing operations.

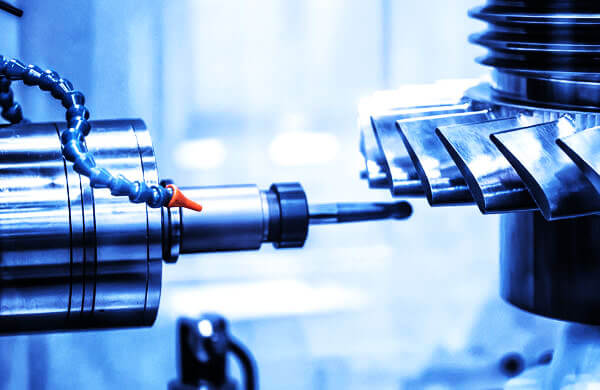

Today, VALMIA is one of the most recognized businesses in the state for its leadership in the design

and fabrication of dies and CNC work (Computerized Numeric Control). We have secured our position as

a key supplier for Japanese automotive companies, including NISSAN subsidiaries, by continuously

striving to reach our customers' satisfaction.

Commitment to Quality and Investment: Our quality management system is certified under the ISO 9001

standard, and every year 10% to 20% of utilities is invested

in the purchase of new equipment to maintain the quality of our service.

We are an organization dedicated to the design and manufacture of stamping and injection molding tools and unique machined parts for the automotive metalworking sector. We carry out our activities using specialized equipment and highly trained personnel committed to continuous improvement and operational efficiency.

To consolidate our position as a leader and benchmark in Mexico in the design and manufacture of stamping, injection, and machining tools for the automotive metalworking sector. We seek to distinguish ourselves through the innovation, quality, and efficiency of our products and services, strengthening customer satisfaction and trust.

Design and produce trustworthy products, guaranteeing the best quality to the costumer, facing the daily technological advance.

GRUPO MODELO

Near 1500 developments in spare parts for beer packaging, as well as in design and assemblies.

NISSAN MEXICANA S.A. DE C.V.

Certified toolmaker and vendor tooling for Nissan Mexicana S.A. de C.V.

YOROZU MEXICANA, S.A. DE C.V.

Design and manufacture of progressive dies, punched and formed white inserts, reverse engineering, and engineering changes.

UNIPRES MEXICANA, S.A. DE C.V.

Design and fabrication of dies, copying of electro-eroded inserts, manufacturing of punches and cutting and forming matrices, reverse engineering, and engineering changes.

PEASA AUTOMOTIVE

Stamping dies for PEASA Automotive.

GESTAMP MEXICO

Dies inserts and 3D scans for GESTAMP Mexico (automotive).

TEXAS INSTRUMENTS DE MEXICO

Design and fabrication of zamak injection molds and related machining.

JATCO MEXICO, S.A. DE C.V.

Design and fabrication of consumable spare parts.

SANS MEXICANA S.A. DE C.V.

Fabrication of inserts for stamping.

EXEDY MEXICO, S.A. DE .C.V.

Stamping dies.

MAIND STEEL S.A. DE C.V.

Stamping dies.

CIA CERVECERA DE COAHUILA

Packaging spare parts.

TACHIS

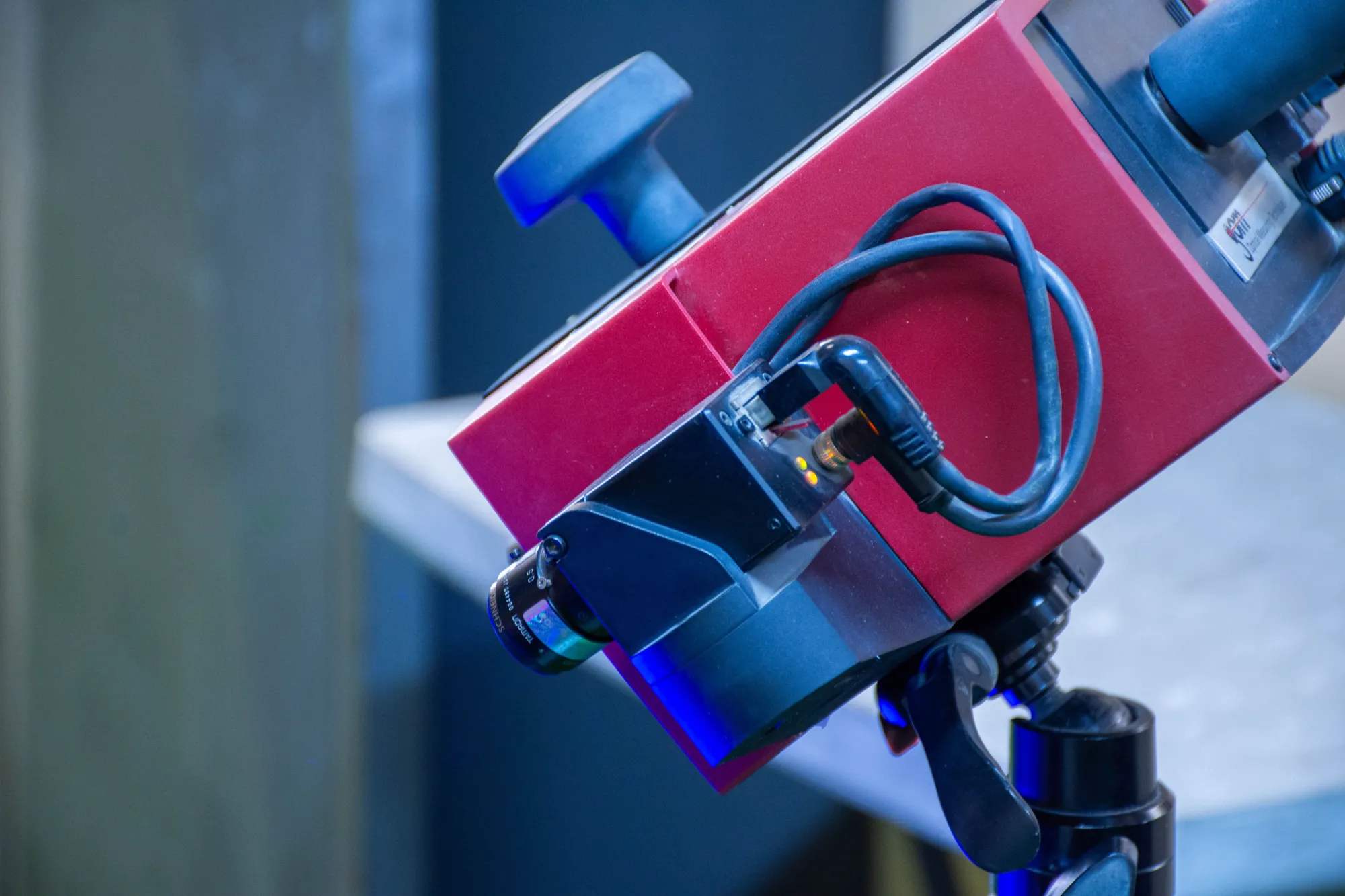

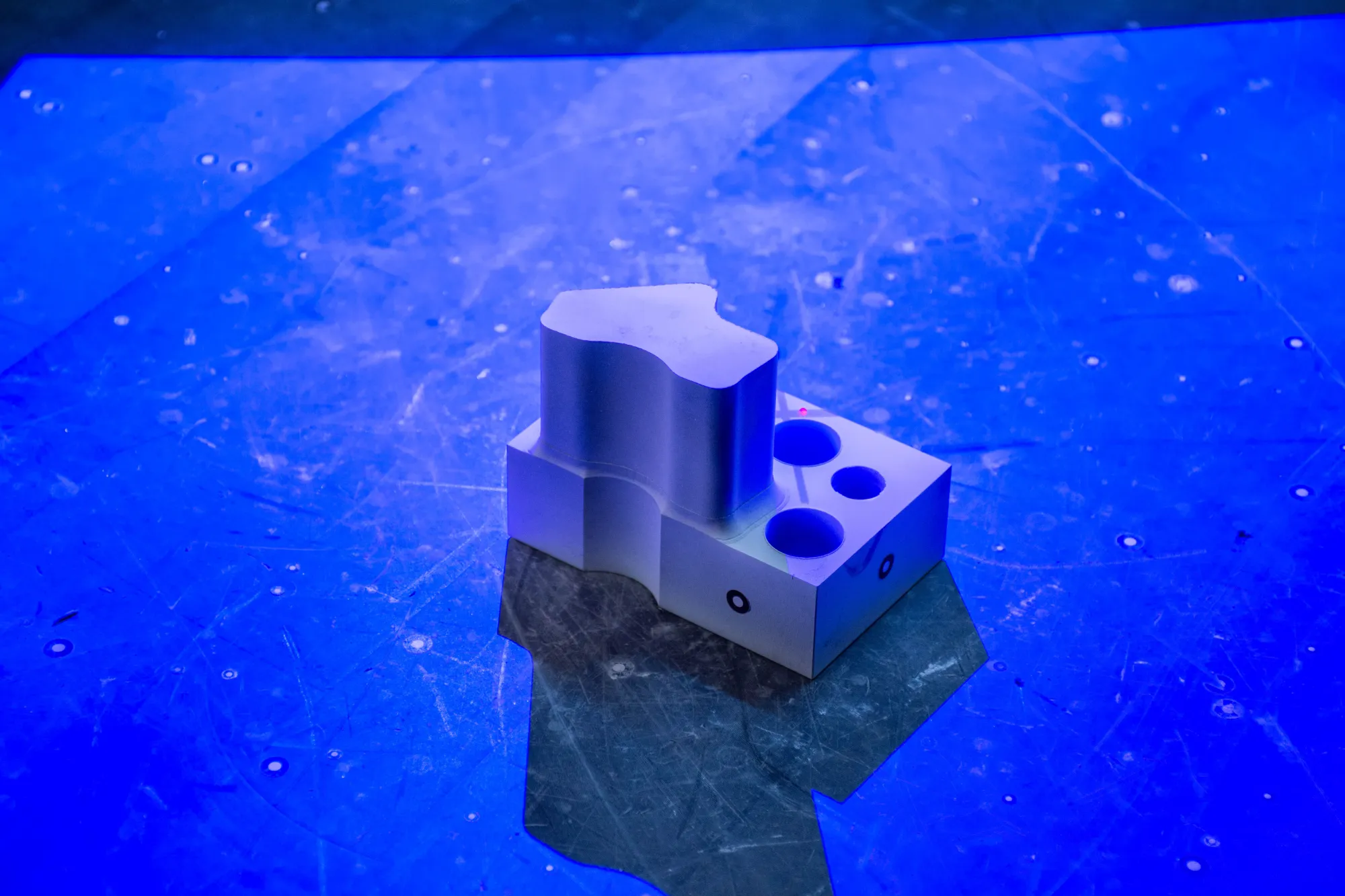

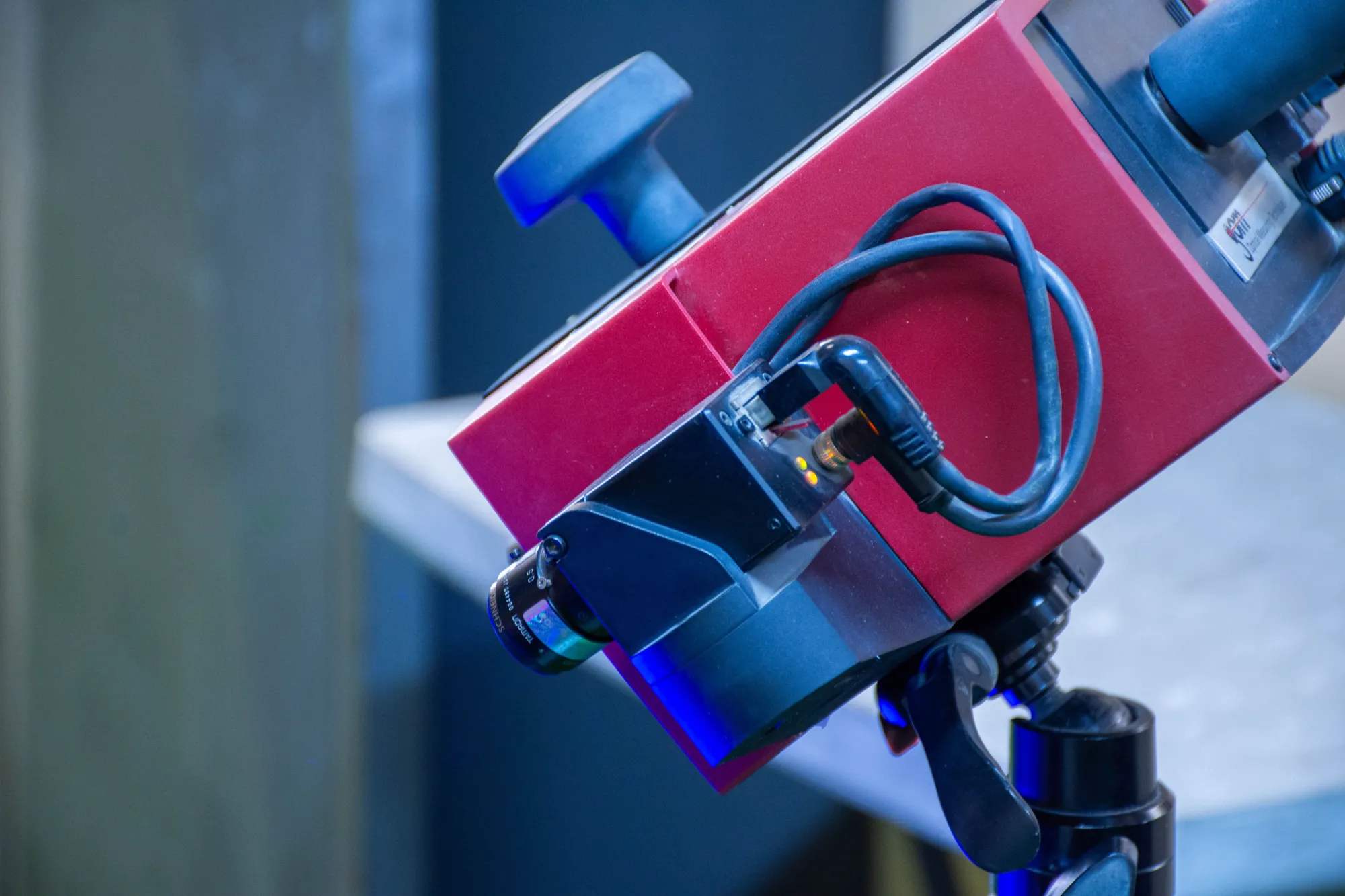

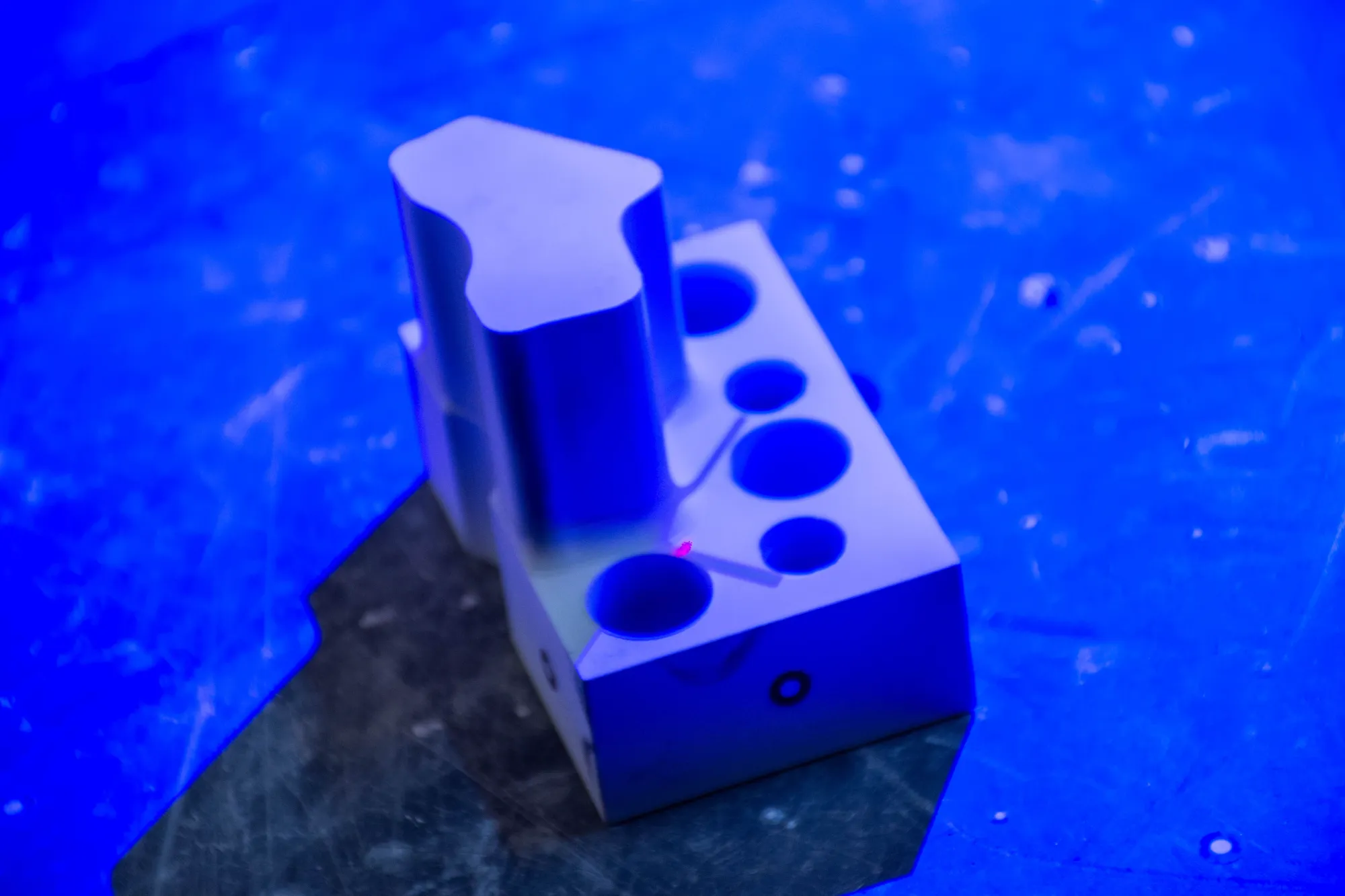

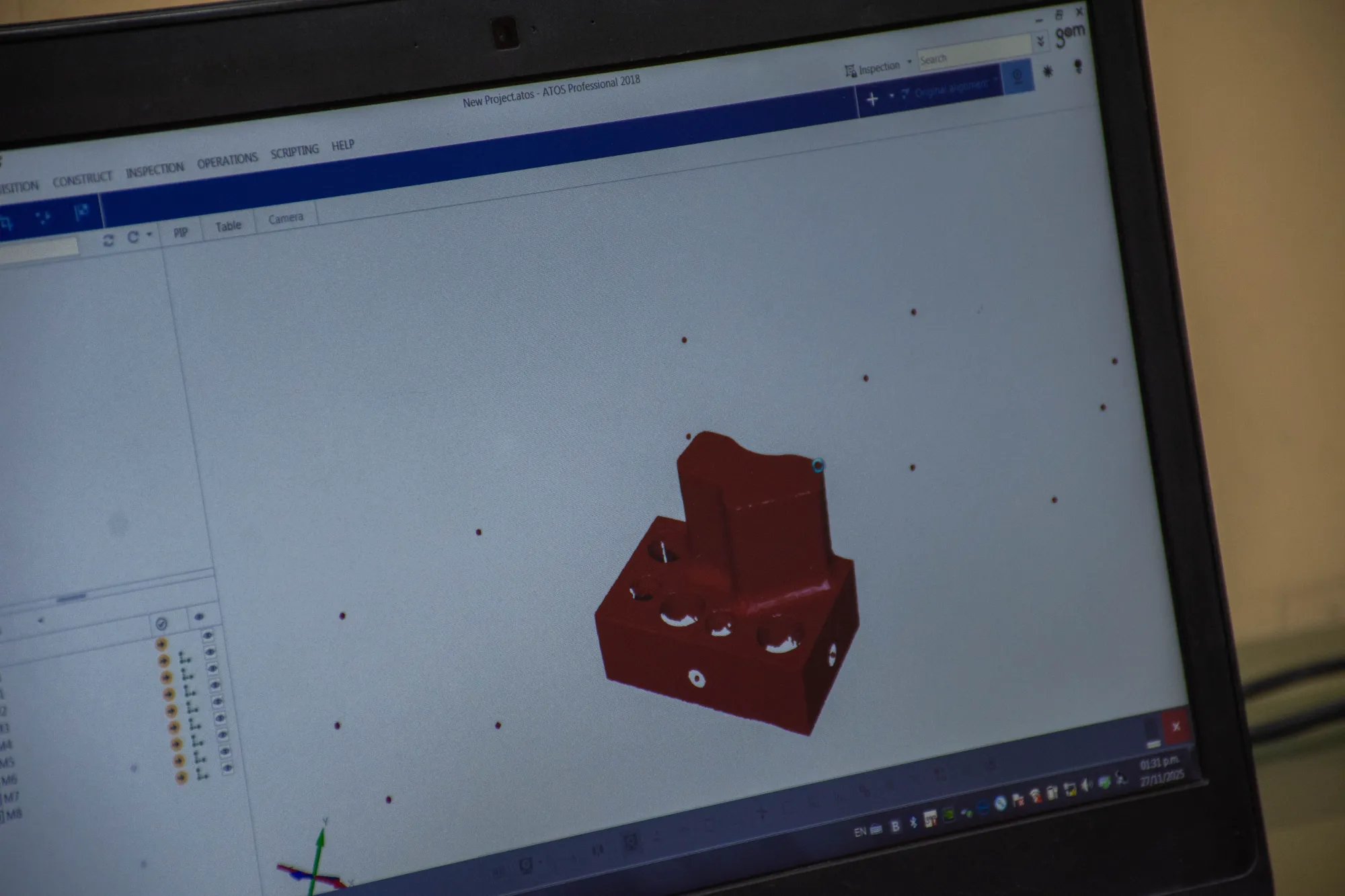

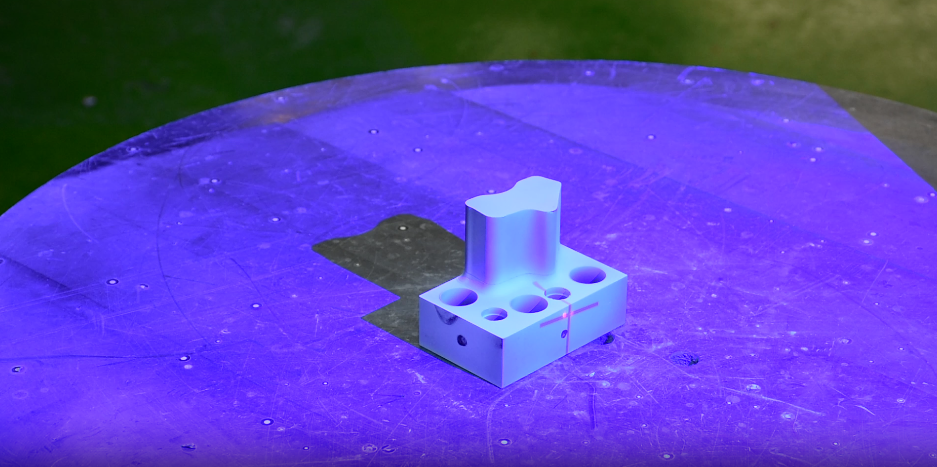

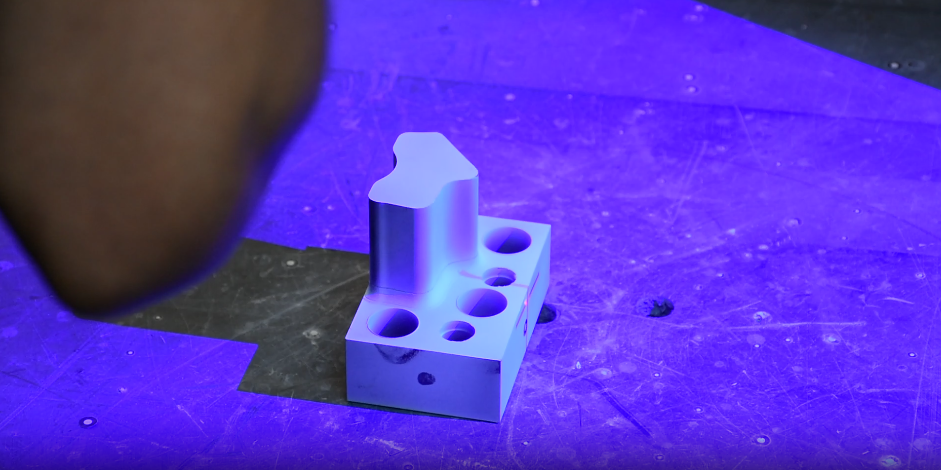

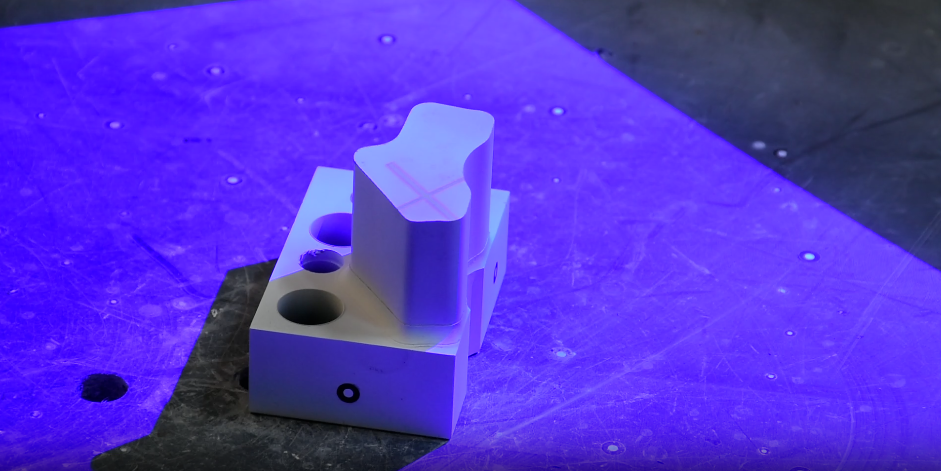

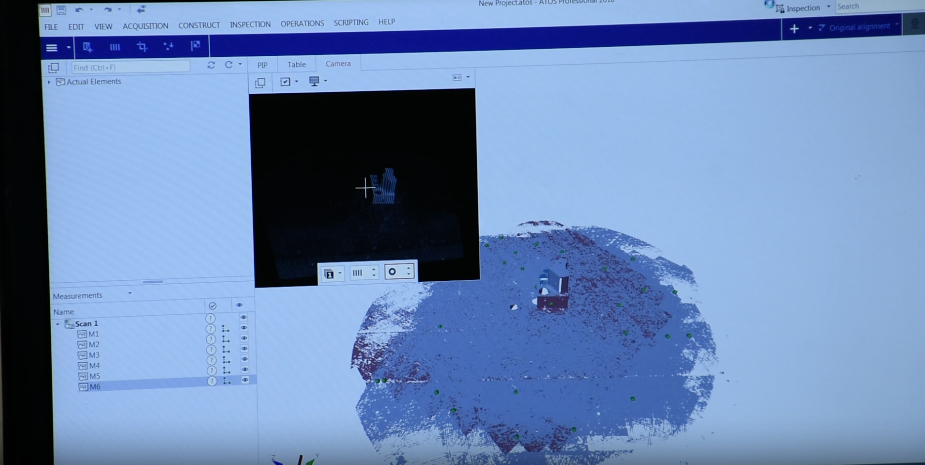

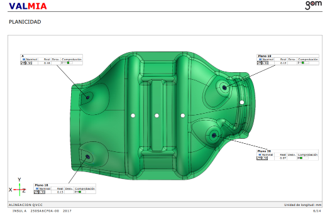

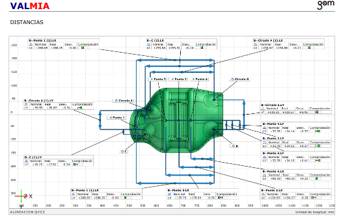

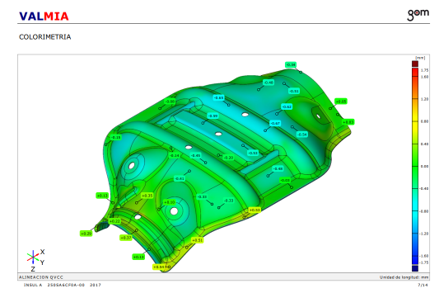

VALMIA integrates ZEISS ATOS Scan, a high-resolution 3D optical system, for exceptionally precise analysis

of every tooling surface.

This tool captures millions of measurement points in seconds, creating accurate digital models for

dimensional verification, mold adjustments, and control of deformation/wear.

3D Scanning Ensures:

With ATOS Scan, we reinforce our commitment to innovation, efficiency, and manufacturing excellence, delivering reliable, high-performance results.

Equipped with state-of-the-art inspection technology, we provide precise measurements, dimensional analysis, and high-resolution 3D digitization through:

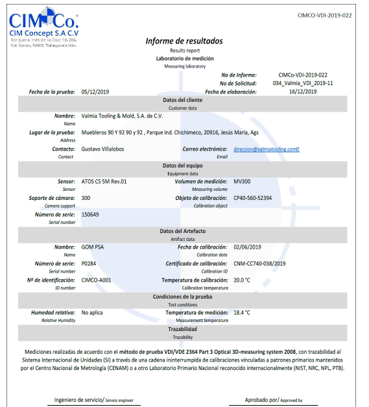

Our ATOS Compact Scan system is certified annually under the VDI/VDE standard, ensuring accuracy and reliability in our 3D scanning and dimensional inspection processes.

This certification validates that our measurements comply with international metrological precision requirements.

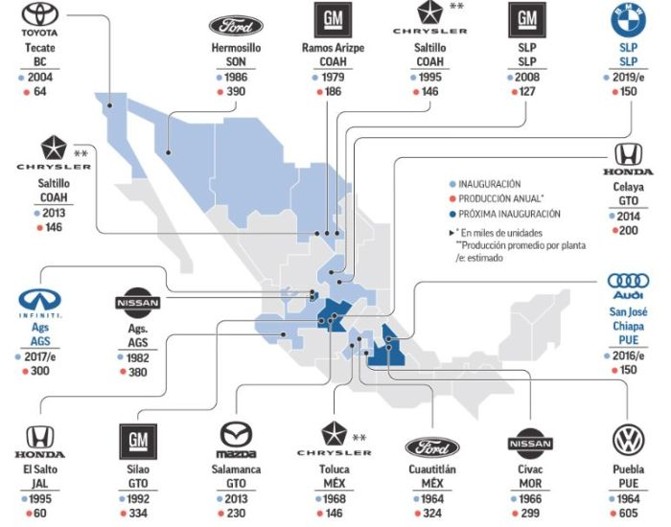

Explore the dynamic automotive production network in Mexico, a key country in the global industry. This map illustrates the location of major manufacturing plants, highlighting the infrastructure that supports our valued clients and business partners. It stands as a testament to the country’s vibrant industrial capacity and ongoing investment in the sector—fundamental elements for our growth and that of our collaborators.